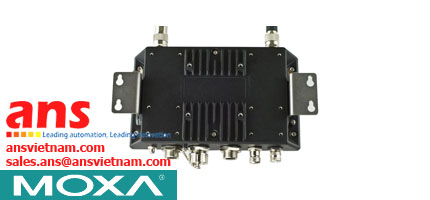

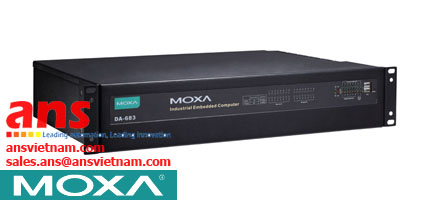

Power Substation Computers DA-662A Moxa vietnam

Xuất sứ: Moxa VietNam

Nhà cung cấp: Moxa VietNam ANS VietNam

Hãng sản xuất: Moxa

Power Substation Computers DA-662A Moxa vietnam

Features

MoxaMacro 500 MHz processor

MoxaMacro 500 MHz processor- 128 MB RAM onboard, 32 MB flash

- 8 to 16 software-selectable RS-232/422/485 serial ports

- 8 to 16 jumper-configurable 1/150 kΩ pull low/high and 120 ohm termination resistors

- 15 kV ESD protection for all serial signals

- Quad 10/100 Mbps Ethernet ports

- USB and CF slots for storage expansion supported

- Standard 19-inch rackmount installation, 1U height

- Wide range of power input voltages from 100 to 240 VAC

- LCM display and keypad for HMI

- Ready-to-Run Linux OS platform

- Robust, fanless design

- Isolated serial port protection models available

Overview

The DA-662A RISC-based, ready-to-run embedded computers are designed for industrial data acquisition applications. The computers have 8 to 16 RS-232/422/485 serial ports, 4 Ethernet ports, and 2 USB 2.0 ports, all based on the MoxaMacro communication processor. In addition, the DA-662A-I-8/16-LX’s serial ports come with high level interference protection. The housing is a standard 1U, 19-inch wide rack-mounted rugged enclosure. The robust, rack-mountable mechanism design provides the hardened protection needed for industrial environment applications, and makes it easy for users to install the DA-662A computers on a standard 19-inch rackmount. The DA-662A computers are ideal for applications that require a distributed embedded technology, such as SCADA systems, plant floor automation, and power electricity monitoring applications.

Application Note

Efficient IIoT Data Processing with High I/O Density Computers ![]()

.jpg) With more and more companies implementing IIoT applications, the demand to connect hundreds or thousands of devices to industrial automation systems has increased dramatically. The DA-720, a high-performance industrial-grade x86 platform, is ideal for such applications. It is based on the lntel® 6th Gen Skylake processor and provides a high density of gigabit Ethernet and serial ports in a 19-inch 2U rack-mountable case, making it an ideal choice for IIoT applications in industrial automation systems.

With more and more companies implementing IIoT applications, the demand to connect hundreds or thousands of devices to industrial automation systems has increased dramatically. The DA-720, a high-performance industrial-grade x86 platform, is ideal for such applications. It is based on the lntel® 6th Gen Skylake processor and provides a high density of gigabit Ethernet and serial ports in a 19-inch 2U rack-mountable case, making it an ideal choice for IIoT applications in industrial automation systems.

Find out how Moxa’s high I/O density rackmount computers can streamline your power, railway, and factory automation applications.......more

White Paper

How to Get the Best Out of the IIoT with Predictive Maintenance ![]()

The Industrial Internet of Things (IIoT) is shaping the way industrial applications are designed and implemented today. The IIoT is ushering in a new era of operational efficiency, information transparency, and economic growth. Innovative ideas on how to collect data, how to transform data, and how to use the data to increase efficiency and reduce costs are sprouting up all around us. The IIoT has bridged the gap between the physical and digital worlds and has created one combined space that provides limitless possibilities. In addition, the relentless pursuit of excellence in the IIoT world has renewed an interest in predictive maintenance solutions that ensure higher equipment reliability and system uptime.......more

The Industrial Internet of Things (IIoT) is shaping the way industrial applications are designed and implemented today. The IIoT is ushering in a new era of operational efficiency, information transparency, and economic growth. Innovative ideas on how to collect data, how to transform data, and how to use the data to increase efficiency and reduce costs are sprouting up all around us. The IIoT has bridged the gap between the physical and digital worlds and has created one combined space that provides limitless possibilities. In addition, the relentless pursuit of excellence in the IIoT world has renewed an interest in predictive maintenance solutions that ensure higher equipment reliability and system uptime.......more

White Paper

Intelligent Automation for the Maintenance and Recovery of Software Platforms

Automation advances in industrial processes increasingly involve using industrial PCs for the control and monitoring of every sort of machinery and process. Yet as industrial PCs penetrate ever further into the automation stack, the problem of data loss and system corruption becomes a critical consideration both for the security issues raised as well as overall system availability. In this white paper we examine the software and hardware features that constitute an effective, fully automated, BIOS initiated, block-level software recovery solution that can be used across any industrial environment, whether following emergency crashes or for automated preventive maintenance......more

Automation advances in industrial processes increasingly involve using industrial PCs for the control and monitoring of every sort of machinery and process. Yet as industrial PCs penetrate ever further into the automation stack, the problem of data loss and system corruption becomes a critical consideration both for the security issues raised as well as overall system availability. In this white paper we examine the software and hardware features that constitute an effective, fully automated, BIOS initiated, block-level software recovery solution that can be used across any industrial environment, whether following emergency crashes or for automated preventive maintenance......more

Making Smart Substations Even Smarter: Enhancing Substation Reliability, Availability, and Maintainability

This paper sketches out a few of the more important concerns that electricity suppliers should account for when planning substation upgrades. The focus is on how best to increase the reliability, availability, and maintainability of power substation automation networks within the context of the IEC 61850 vision, to give electricity suppliers a clear idea of the design procedures, device tolerances, and hardware and software features they should expect from the engineers and manufacturers who design and build their networking and computing devices.......more

This paper sketches out a few of the more important concerns that electricity suppliers should account for when planning substation upgrades. The focus is on how best to increase the reliability, availability, and maintainability of power substation automation networks within the context of the IEC 61850 vision, to give electricity suppliers a clear idea of the design procedures, device tolerances, and hardware and software features they should expect from the engineers and manufacturers who design and build their networking and computing devices.......more

Using MMS and SNMP to Integrate IT Management for Substation Automation

The devices that electrical substation automation systems are built from depend on highly precise, time-critical communications. Substation thus often use highly specialized monitoring systems to tackle this problem, but can approach it using different technologies. The most up-to-date, “smart” substations use the Manufacturing Messaging Specification (MMS) for communications among IEC 61850 intelligent electronic devices (IEDs), allowing SCADA to monitor and control IED states as well as process switchgear and transformer data directly. However, IT networking devices have been increasingly applied in IEC 61850 systems, and this equipment communicates using SNMP. Consequently, in the modern substation automation industry it’s clear that, for the time being, SNMP and MMS will continue to exist side-by-side. For designers and integrators of electrical substation equipment, bringing both MMS and SNMP support to IT equipment is an ideal, one-size fits-all alternative that allows for the greatest flexibility and adaptability around........more

The devices that electrical substation automation systems are built from depend on highly precise, time-critical communications. Substation thus often use highly specialized monitoring systems to tackle this problem, but can approach it using different technologies. The most up-to-date, “smart” substations use the Manufacturing Messaging Specification (MMS) for communications among IEC 61850 intelligent electronic devices (IEDs), allowing SCADA to monitor and control IED states as well as process switchgear and transformer data directly. However, IT networking devices have been increasingly applied in IEC 61850 systems, and this equipment communicates using SNMP. Consequently, in the modern substation automation industry it’s clear that, for the time being, SNMP and MMS will continue to exist side-by-side. For designers and integrators of electrical substation equipment, bringing both MMS and SNMP support to IT equipment is an ideal, one-size fits-all alternative that allows for the greatest flexibility and adaptability around........more

| Hardware Specifications | |

| • Computer | |

| CPU | MoxaMacro 500 MHz |

| OS | Embedded Linux (pre-installed) |

| DRAM | 128 MB onboard |

| Flash | 32 MB onboard |

| • Ethernet Interface | |

| LAN | Auto-sensing 10/100 Mbps ports (RJ45) x 4 |

| Magnetic Isolation Protection | 1.5 kV built-in |

| • Serial Interface | |

| Serial Standards | 8 to 16 RS-232/422/485 ports, software selectable (8-pin RJ45) |

| ESD Protection | 8 kV contact, 15 kV Air ESD protection for all signals |

| Surge Protection | 2 kV line-to-line and 4 kV line-to-ground surge protection, 8/20 μs waveform (DA-662A-I-8/16-LX only) |

| Insulation | 500 V (DA-662A-I-8/16-LX only) |

| Isolation | 2 kV digital isolation (DA-662A-I-8/16-LX only) |

| Termination Resistor | 120 ohm, jumper selectable |

| Console Port | RS-232 (all signals), RJ45 connector |

| • Serial Communication Parameters | |

| Data Bits | 5, 6, 7, 8 |

| Stop Bits | 1, 1.5, 2 |

| Parity | None, Even, Odd, Space, Mark |

| Flow Control | RTS/CTS, XON/XOFF, ADDC® (automatic data direction control) for RS-485 |

| Baudrate | 50 bps to 921.6 Kbps (supports non-standard baudrates; see user’s manual for details) |

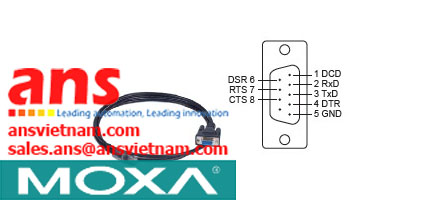

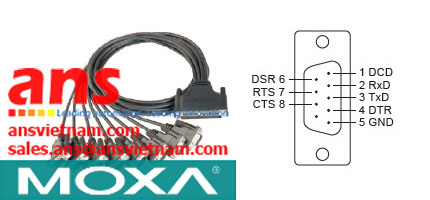

| • Serial Signals | |

| RS-232 | TxD, RxD, DTR, DSR, RTS, CTS, DCD, GND(DA-662A-I-8/16-LX only: TxD, RxD, RTS, CTS, GND) |

| RS-422 | TxD+, TxD-, RxD+, RxD-, GND |

| RS-485-4w | TxD+, TxD-, RxD+, RxD-, GND |

| RS-485-2w | Data+, Data-, GND |

| • LEDs | |

| System | OS Ready |

| LAN | 10/100M x 4 |

| Serial | TxD, RxD (16 of each) |

| • Mini Screen with Push Buttons | |

| LCD Panel | Liquid Crystal Display on the case, 2 x 16 text mode |

| Push Buttons | Four membrane buttons for convenient on-site configuration |

| • Physical Characteristics | |

| Housing | SECC sheet metal (1 mm) |

| Weight | 4.3 kg (9.56 lb) |

| Dimensions | Without ears: 440 x 45 x 237 mm (17.32 x 1.77 x 9.33 in) With ears: 480 x 45 x 237 mm (18.90 x 1.77 x 9.33 in) |

| Mounting | Standard 19-inch rackmount |

| • Environmental Limits | |

| Operating Temperature | -10 to 60°C (14 to 140°F) |

| Storage Temperature | -20 to 80°C (-4 to 176°F) |

| Ambient Relative Humidity | 5 to 95% (non-condensing) |

| Anti-Vibration | 1 g @ IEC-68-2-6, sine wave (resonance search), 5-500 Hz, 1 Oct/min, 1 Cycle, 13 mins 17 sec per axis |

| • Power Requirements | |

| Input Voltage | 100 to 240 VAC auto ranging(47 to 63 Hz for AC input) |

| Power Consumption | 20 W |

| • Standards and Certifications | |

| Safety | UL 60950-1 |

| EMC | EN 61000-6-2/6-4 |

| EMI | CISPR 22, FCC Part 15B Class A |

| EMS | IEC 61000-4-2 ESD: Contact: 8 kV; Air: 15 kV IEC 61000-4-3 RS: 80 MHz to 1 GHz: 3 V/m IEC 61000-4-4 EFT: Power: 1 kV; Signal: 0.5 kV IEC 61000-4-5 Surge: Power: 2 kV; Signal: 4 kV IEC 61000-4-6 CS: Signal: 3 V/m IEC 61000-4-8 1 A/m IEC 61000-4-11 |

| Green Product | RoHS, CRoHS, WEEE |

| • Reliability | |

| Alert Tools | Built-in buzzer and RTC (real-time clock) |

| Automatic Reboot Trigger | Built-in WDT (watchdog timer) |

| • MTBF (mean time between failures) | |

| Time | DA-662A-8-LX: 272,913 hrs DA-662A-16-LX: 177,580 hrs DA-662A-16-DP-LX: 177,260 hrs DA-662A-I-8-LX: 268,332 hrs DA-662A-I-16-LX: 189,455 hrs |

| Standard | Telcordia (Bellcore) Standard TR/SR |

| • Warranty | |

| Warranty Period | 5 years |

| Details | www.anhnghison.com |

| Software Specifications | |

| • Linux | |

| OS | Linux 2.6.38.8 |

| Web Server (Apache) | Allows you to create and manage web sites; supports PHP and XML |

| Terminal Server (SSH) | Provides secure encrypted communications between two un-trusted hosts over an insecure network |

| File System | JFFS2 (on-board flash) |

| Internet Protocol Suite | TCP, UDP, IPv4, SNMPv1, ICMP, ARP, HTTP, CHAP, PAP, SSH 1.0/2.0, SSL, DHCP, NTP, NFS, Telnet, FTP, TFTP, PPP, PPPoE, SNMP v1/v2, SSL, OpenVPN |

| Internet Security | iptables firewall |

| Dial-up Networking | PPP Daemon for Linux that allows Unix machines to connect to the Internet through dialup lines, using the PPP protocol, as a PPP server or client. Works with ‘chat’, ‘dip’, and ‘diald’, among (many) others. Supports IP, TCP, UDP, and (for Linux) IPX (Novell). |

| File Server | Enables remote clients to access files and other resources over the network |

| Watchdog | Features a hardware function to trigger system reset in a user specified time interval (Moxa API provided) |

| Application Development Software | • Moxa API Library (Watchdog timer, LCM, keypad, Moxa serial I/O control) • GNU C/C++ cross-compiler • GNU C library |

![Cables-CBL-M12[FF5P]-OPEN-100-IP67-Moxa-vietnam.jpg](/Images/products/thumb/Cables-CBL-M12[FF5P]-OPEN-100-IP67-Moxa-vietnam.jpg)